| Item | Unit | DK7735 |

| Travel of X,Y,Z | mm | 350*450*400 |

| Table size | mm | 490*730 |

| Cut taper/thickness | °/mm | 3/80 |

| Cut accuracy | mm | 0.015 |

| Max cut speed | mm²/min | 180 |

| Roughness accuracy | um | 1.2-2.5 |

| Wire diameter | mm | 0.13-0.2(normally0.18) |

| Max.electrical current | A | 10 |

| Power | Kw | 1.6 |

| Voltage | V/Hz | 220/380/415V , 50/60Hz |

| Max load of table | Kg | 400 |

| Weight of machine | Kg | 1250 |

| Machine Dimensions(L*W*H) | mm | 1550*1150*1750 |

| Item | Unit | DK7735 |

| Controller Model | Vertical Cabinet | |

| CNC system | AutoCut /X8 | |

| Program software | AutoCad | |

| Processing basic | Windows XP/Windows 7 | |

| Handle controller | Yes | |

| Single/Multi Cut | optional | |

| transducer control | Yes | |

| Max. Processing Current | 10A |

-

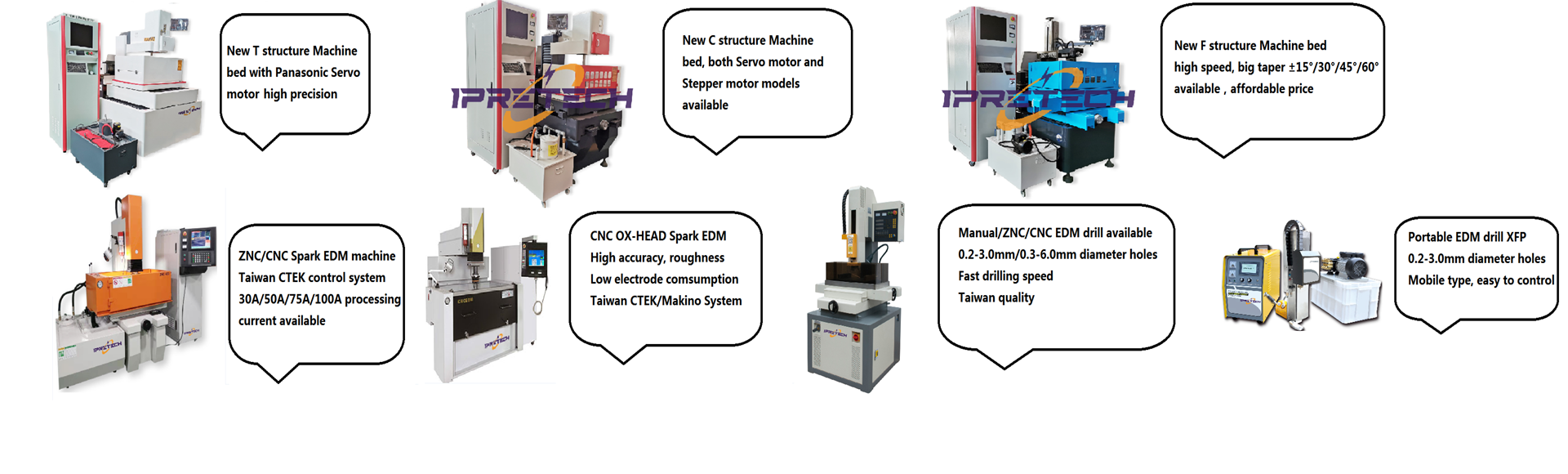

Ipretech Wire cut EDM machining is mainly used to process various punch tie, plastic mold, Powder metallurgy mold and etc, which have 2D and 3D faces combined, or components. It can also cut various sample plate, magnetic steel, Silicon Steel Sheet, semi-conductive material or precious metal. Furthermore, it is able to do tiny machining, abnormal shape groove or machining of standard defect of sample parts, widely used in electrics, precious machine tools, light industry, army industry and so on.